Requirements

for a Drilling and Wells Interoperability Standard

Increase safety and efficiency through the development

of a standardized interface that enables collaborative automation of

wellbore construction.

Executive Summary

![]()

The Drilling and Wells Interface Standards group is developing a set of

standards for an open, interoperable and secure

interface between participants in well construction. External companies such as

service companies, operators and equipment suppliers,

will interface their technology to the drilling rig using the elements of the

standards. The technologies could be algorithms, models, automation advisors or

controllers, or various auxiliary equipment with their own control systems.

This paper serves to document an overview of the intended scope of the

standards, and a view of the DWIS requirements.

Introduction

There is increasing development and deployment

of systems at the rigsite for drilling process

automation. These systems deliver advice and equipment set points to the rig.

They therefore require an interface to the rig operating and control systems.

The number of players interfacing to a large number of rig

operating and control systems in a bespoke fashion is expensive and carries a

significant HS&E risk. There is a significant cost to all parties in

developing and maintaining reliable interfaces for each drilling installation.

There is therefore a need to define a standard that

allows for interoperable operations in a safe and secure fashion. The technical

benefits of such standards include increased fidelity, efficacy, integrity and security of operations.

The lack of standards for an interoperable

interface is a significant impediment to rapid development of systems

automation at the rigsite.

The Drilling and Wells Interoperability

Standards (DWIS) group is currently developing and demonstrating a set of

interoperability standards for this multi-player environment. This document

gives and introduction to the scope of this work, and a list of requirements

for the standards. It is by no means a complete document, but it should support

a working discussion of DWIS.

It is important to understand that DWIS is

developing a set of standards defining an interface between software

components. The requirements listed in this document are, therefore, for the

multi-player software environment at the rigsite,

designed to permit reliable and secure plug and play operations.

System Elements

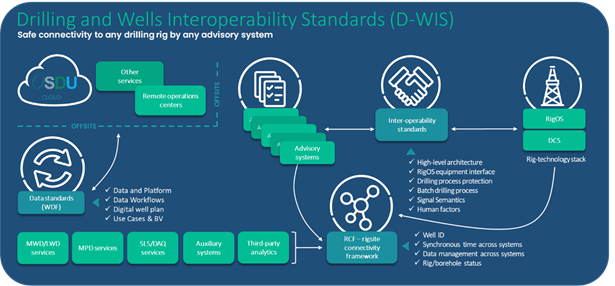

Figure 1: Components shown in light blue are

DWIS components; all others (green) represent proprietary components. The main

DWIS elements are an interoperable standard for drilling rig interface, a rig

connectivity framework for all components located on the wellsite, and data

standards for onsite and data exchange. The OSDU Wells Data Foundation (WDF) is

handling the last item.

The scope

of the Drilling & Wells Interoperability Standards (DWIS) covers the

wellsite (rigsite) and the exchange of data and

commands in real-time. The four elements common to all players are the rig

connectivity framework, the interoperability standards between third party

applications and the rig technology stack, data schema and exchange standards

for the wellsite, and connectivity to the Open Subsurface Data Universe (OSDU)

via their Edge Standard. This document contains the requirements for the first

two components, which are part of DWIS. The data schema and exchange standards

are part of the OSDU Wells Data

Foundation initiative. The diagram above shows proprietary components,

colored green, which are out-of-scope. The standard specifies only software,

not hardware, and does not extend to communication protocols or user interfaces.

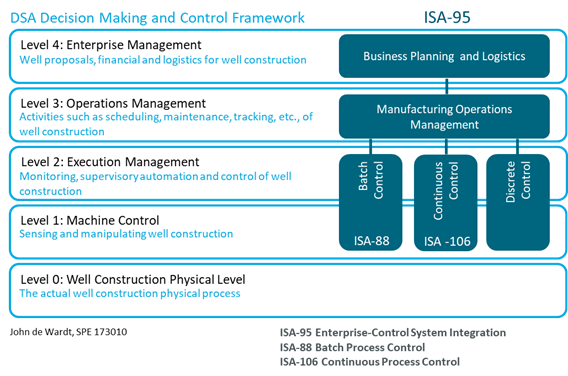

Figure 2: Systems Automation Standards,

shown in relation to the Drilling Systems Automation Decision making and

Control Framework, described in SPE 173010, 2015, Drilling Systems Automation

Roadmap - The Means to Accelerate Adoption

In terms of

standards, ISA-95, ISA-88 and ISA-106, among others, are relevant to DWIS. In

the DSA Decision Making Framework, DWIS occupies primarily level 1 and 2,

although later components such as batch processing will be at level 3. Some of

the terminology used in DWIS, has evolved from ISA-88, the batch processing

standard, although the implementation is focused on well construction and the

terminology is therefore, more narrow than in ISA-88.

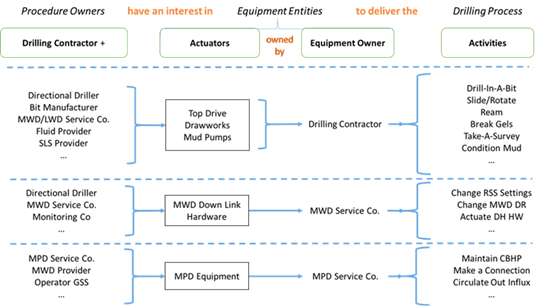

Figure 3: The DWIS Interface Construct in

ISA-88 Terminology

Fique 3

shows the DWIS rig interface construct in ISA-88 terms: ‘procedures use

equipment to deliver a process’. There are several levels depending on who owns

the equipment. DWIS will develop an interface standard that applies to all

examples in this figure. It does this through a construct in which the

procedures are in advisor applications that have optional third-party

equipment; these advisor applications communicate via a DWIS interface with the

Rig OS or DCS.

The

remainder of the document deals with the requirements for the DWIS components

in figure 1.

Requirements

There are requirements

in several aspects of the system, loosely grouped as follows:

·

Requirements related to commercial

aspects of the standards

·

Requirements related to scope of the

standards

·

Requirements related to Drilling

Process Protection

·

Requirements related to the Semantic

of RT Signals

·

Requirements related to High Level

Architecture

·

Requirements related to the RIG OS

(ADCS) Equipment Interface

Commercial Requirements

These are

requirements related to deployment of DWIS in a commercial environment. These

requirements drive the selection of relevant technologies by asset owners,

software and algorithm developers, and system integrators.

|

Requirement ID |

Commercial Requirement |

Considerations |

|

|

DWIS shall

provide an open development environment, supported through an open

architecture |

Adoption of an

open standard will promote competition through new business models and

offerings in the marketplace |

|

|

DWIS shall

support best-in-class solutions from multiple vendors in a single system |

Few, if any,

vendors provide best in class solutions for the full scope of well

construction. This requirement opens up the market

for vendors to provide their best-in-class solutions to any system. |

|

|

Systems built

using DWIS shall support conforming components from any competitive vendor |

This prevents

vendor lock-in, where the end user can only use products from one vendor. |

|

|

Systems built

following DWIS shall substantially reduce the effort to integrate different

vendor systems |

This is a key

requirement. Reducing the cost and time of integrating systems and components

from different vendors into a single system is of commercial value. |

|

|

Preservation of

the owner’s configuration and programming intellectual property with minimal

rework from one generation of DWIS to the next. |

There is

significant cost and time spent by owners in defining their advising and control

strategies. Requiring rewrites at generational changes means it is often too

expensive to upgrade. |

|

|

Participation in

the development and use of DWIS shall not jeopardize the intellectual

property of participants. |

DWIS

respects intellectual property concerns and components using DWIS shall not

expose their intellectual property. This is required to have a healthy

commercial environment for DWIS users. |

|

|

There shall be no

cost to obtaining DWIS |

DWIS is an open standard,

and a no-cost way of obtaining these standards is critical to enabling

adoption in the marketplace. |

Scope Requirements

The requirements

governing scope constrains the relevance of the DWIS interface. In particular,

the DWIS interface is only relevant to data exchange, and process and batch

automation at the rigsite between third party

equipment and rig drilling control systems. DWIS also incorporates activities

such as the ISA95/IEC 62264 Enterprise-Control System Integration standards,

the ISA88 Procedure Automation for Batch Process Operations standards, and the

DSA Decision Making and Control Framework described in John de Wardt et al,

2015, Drilling Systems Automation Roadmap - The Means to

Accelerate Adoption, SPE 173010, https://doi.org/10.2118/173010-MS

|

Requirement ID |

Scope Requirement |

Considerations |

|

|

DWIS shall apply

to automation of well construction at the wellsite |

Systems

conforming to DWIS are activities related to well construction, such as

drilling, running casing, cementing, etc. DWIS is concerned with

interoperability in the automation of these multiplayer activities |

|

|

The scope of DWIS

shall encompass ISA95/IEC62264 levels 1, 2 and 3. |

DWIS compliant

components will include sensing, actuating, control, advising, visualization,

and historical data collection. The DSA Decision making and Control Framework

in paper https://doi.org/10.2118/173010-MS shows this standard applied to

drilling automation. |

|

|

DWIS shall apply

to rigsite connections between third party

applications and equipment, and the Rig drilling control systems: ADCS or

DCS. |

Connection

and control of rig equipment remains the responsibility of the ADCS or DCS.

DWIS does not apply to these interfaces. |

|

|

DWIS shall apply

to data exchange, process automation, and batch automation of well construction

activities. |

Connection of third party applications for observation and control,

leading to batch control of well construction |

|

|

DWIS will use

industry standard communications protocols, and other existing standards, as

needed and as specified by its members |

Defining

communications protocols are out of scope of DWIS |

Drilling Process

Protection Scope Requirements

Drilling

process protection is composed of at least three types of functionalities:

·

Safe Mode Management (SMM): If for any reason, an automated

control function fails or the connectivity between a 3rd party app

and the RigOS is lost, the RigOS applies a series of actions to put the

drilling machines in a state that is safe for the current operation. This state

lasts for at least a few tens of second in order to

leave time for the human operator to regain control of the situation even

though his situation awareness may have been low. In the context of DWIS, the only

addressed SMM functions are those linked to the protection of the drilling

process. i.e., SMM functions that deal with the protection of the drilling

machines are outside the scope of DWIS.

·

Fault, Detection, Isolation and

Recovery (FDIR): If

a drilling process incident occurs, it is important to respond as quickly as

possible. FDIR functions monitor continuously the process and are capable of detecting when an abnormal situation has

started. After detection, the FDIR function proceeds with an immediate response

to keep the process as safe as possible. Then after identification of the cause

of the dysfunction, it applies procedures to isolate the problem. Finally, when

isolation has been successful, it applies procedures to recover from the

problem and get ready to resume the original normal command. FDIR functions apply

when automated control functions are active, but also when human operators

control the machines. A failure of the isolation or recovery procedures may

trigger SMM functions. In the context of DWIS, only FDIR functionalities that

concern the drilling process are addressed. In other words, DWIS does not

interfere with FDIR functionalities that protect the drilling machines. FDIR is

a subfield of control engineering that concerns itself with

monitoring a system, identifying when a fault has occurred, and pinpointing the type of

fault and its location (see https://en.wikipedia.org/wiki/Fault_detection_and_isolation)

·

Safe Operating Envelope (SOE): Commands sent to the drilling

machines shall be within acceptable limits with the regards to the tolerances

of the drilling process. The RigOS combines the safe operating envelopes for

the drilling process with the safe operating limits that protect the drilling

machines. SOE functions apply for both human operator and automated function

commands. It is not in the scope of DWIS to address SOE functionalities concerning

the protection of the drilling machines.

|

Requirement ID |

Scope Requirements common for SMM, FDIR and SOE |

Considerations |

|

|

DWIS will enable

the description and transmission of DPP information from an external

application to the ADCS or DCS on the rig. |

The purpose of

this work is not to solve how to generate the parameters of the DPP

functions but assist in transmitting information across computer system

boundaries. |

|

|

DWIS’s interface

for DPP functionalities shall be flexible to account for a wide range of ADCS

or DCS’ supported DPP functionalities. |

The purpose of

this work is not to impose a functionality level for DPP functions

implemented in the ADCS or DCS, but to allow external application to utilize

only one interface (the DWIS interface) to access multiple ADCS or DCS

solutions instead of having to adapt for a multitude of different solutions. |

|

|

The DWIS

interface for DPP functionalities shall be simple to use both on the ADCS or

DCS side, and on the external application side. |

DWIS shall avoid

imposing any restrictions to either the ADCS or DCS, or the external

application. For example, there shall not be a restriction on the programming

languages used on each side of the interface. |

|

|

It is not within

the scope of DWIS to provide a solution for concurrent contributions of

parameters for DPP functionalities. |

The ADCS/DCS shall

have a strategy to manage concurrent access for DPP functionalities. |

|

|

The DWIS

interface shall allow the ADCS or DCS to describe its supported

functionalities such that external application can adapt the passage of

parameters accordingly. |

A form describing

capabilities shall be available so that both sides of the interface can agree

on how to pass parameters. |

|

|

It is not in the

scope of DWIS to address DPP configurations that require sub-second updates. |

Requiring

sub-second updates demands tightly integrating the external

application into the ADCS or DCS. |

|

|

The DWIS

interface for DPP functionalities shall enforce a form of detection for loss

of connection between the two sides of the interface. |

It is important to

detect a connection outage between the two sides of the interface, and to

execute SMM procedures the ADCS or DCS side in such an eventuality. |

Semantic of RT Signals

Requirements

Drilling real-time signals are currently

accessible through different real-time data sources, including WITS0, WITSML,

OPC-DA, OPC-UA, API, etc. With such real-time data sources, the drilling

real-time signals either are in predefined positions in records, e.g., WITS0,

or are accessible through a mnemonic in a time-based log, e.g., WITSML, or

other sort of tag reference, e.g., OPC-DA. To access the correct real-time data

channel, one must know beforehand where to find the information, i.e., the

mnemonic, tag or position in which record.

Furthermore, there is very limited metadata associated with the signal. When

metadata information is available, it is in a statically defined format.

In practice, drilling operations are evolving

constantly, and the availability of drilling real-time signals changes almost on a daily basis. Therefore, personnel in maintaining

support applications for signals, spend much time updating which signals are

now available and where to find them. Also, as metadata is very limited, such

applications cannot take full advantage of the actual qualities and

uncertainties associated with the available signals. In addition, different

applications exchange very few calculated signals, simply because it is already

cumbersome to connect to measured signals. This in turn reduces the possibility

of achieving synergies between the different systems that are monitoring and

controlling the drilling process. Finally, it is difficult to create automatic

quality control of available drilling real-time signals since connecting them

requires a lot of work.

By defining a flexible and generic way to

describe the semantic of real-time signal, it is possible address most of these

issues - by making available facts about each available signal. These facts

describe the meaning of the signal. A potential consumer of the signal can read

those facts and determine whether the signal corresponds to its requirement or

not. The consumer discovers real-time signals dynamically based on

characteristics that are important for its application.

Various consumer applications may have

different perspectives on what is a relevant signal for their own

functionality, and they can choose dynamically the most relevant available

drilling real-time signal. In addition, a consumer application can make

available calculated signals that may be of interest for other applications. By

providing the semantic of these additional signals, they provide an opportunity

for other applications to discover them.

|

Requirement ID |

Semantic RT Signal Requirement |

Considerations |

|

|

DWIS will enable

the description of the semantics of drilling real-time signals. |

By exposing the

semantic of each available signal, it is possible for any application to

discover and choose which signal is of interest for its own functionality |

|

|

The description

of the semantics of drilling real-time signals proposed by DWIS shall be

flexible and generic. |

It is important

that the solution chosen for describing the semantic of drilling real-time

signal can support currently available signals and future signals that are

not yet “invented”. |

|

|

The description

of the semantics of drilling real-time signals shall rely on a very concise

method. |

As there are tens

of thousands of real-time signals at the rig site, and there can be even more

signals that may be made available when calculated signals are also exchanged,

it is important that the proposed solution to describe the semantics of

real-time signals is not subject to combinatorial explosion. |

|

|

The chosen method

to provide a semantic description of drilling real-time signals shall support

multiple data sources. |

The drilling

process involves many different service companies. The constellation of the

service companies that are present during the drilling process evolves

constantly. Therefore, it is important that the proposed solution is

compatible with a very changing environment. |

|

|

The introduction

of the description of the semantics of drilling real-time signals shall not affect

refresh rates, delays, uncertainty, and quality of the actual signals. |

As there are

already problems with latency, refresh rates, uncertainty

and data quality in general, it is important that the introduction of

semantical description does not exacerbate the current situation. |

|

|

The semantic

description of drilling real-time signals shall be completely agnostic to

which programming languages, operating systems or any other computer

specificities is used by the data provider or the data consumer. |

The different

service providers utilize many different software solutions, including, PLCs,

IoT, Servers, handheld computers, etc., running many different types of OS

like Windows, Linux, iOS, Android, Step7… and programmed in various

languages, e.g., Python, Java, C, C++, C#, … Also, new computer solutions,

new OS and new programming languages will arise in the future. It is

important that the chosen solution does not block the access to the DWIS

interoperability to any of those possibilities. |

|

|

The semantic

description of drilling real-time signals shall be compatible with the

access-control rules implemented in any drilling operations. |

Typically, the

proposed solution shall contain an AAA (Authentication, Authorization and

Accounting) strategy so that only authorized parties can access the

information. |

High Level Architecture

Requirements

High-level architecture requirements covers the system organization, so that it is scalable to batch

processing of wellbore construction. It is concerned with the hierarchy of

procedures, the multiplayer advisor environment, authorization and

authentication of components, and the state of the various activities on both

surface and downhole. These requirements ensure an architecture that is

relevant to batch processing and, in future, well construction orchestration.

|

Requirement ID |

Requirement |

Considerations |

|

|

Define approach

for batch procedure development. |

The standards

shall be capable of scaling to batch processing of a wellbore, where a batch

is a borehole section, fluid for a borehole section, etc. |

|

|

Define approach

for handling multiple advisors during a phase of drilling. |

There could be

multiple advisors, from multiple players, running in parallel during any

phase of the drilling operation |

|

|

Define approach

for handling hierarchy of drilling phases and handling of advisors. |

Wellbore

construction is a hierarchy of phases, as partially defined in IADC DDR Plus.

The architecture shall be capable of handling multiple advisors across and

between these phases. |

|

|

Define approach

for contextualization of common data items. |

DWIS is primarily

concerned with data exchange, and it is therefore important to define – and

know – the context of the data. |

|

|

Define AuthN/Z for integrating into system. |

Advisors

(applications) need to be fully authenticated and authorized before becoming

members of the system |

|

|

Define

methodology for communicating to Driller from Batch. |

As part of the

architecture, it should be specified how the driller communicates with batch

processes (and sub-processes) to develop a standard, reliable, interface |

|

|

Define method of

registering Batch processes relative to a phase of Drilling. |

A batch process

may be valid and operational across multiple drilling phases, and this

validity must be known to schedulers and third party

advisors |

|

|

Identify and

address cross cutting concerns including but not limited AuthN/Z,

Logging, Batch Processing, Advisor Registration, Advisor State Management,

Drill State, Rig State |

Various concerns

may apply to all components in DWIS. These need to be identified and

addressed in a scalable fashion |

|

|

Architecture

integration with Drill State and Rig State inference. |

Rig State (rig

activity) and Drill State (borehole activity and condition) are relevant to

registered advisors. They may prepare to run, execute, or terminate,

depending on these states. Therefore, definitions should be agreed upon that

are scalable across control and batch processing. |

RIG OS (ADCS) Equipment

Interface Requirements

|

Requirement ID |

Requirement |

Considerations |

|

|

Rig equipment

interfaces will support the various roles of well construction. Currently we are defining ·

Operational view – Equipment agnostic interface that

expose normalized rig functions and support safe operations. ·

Engineering view – Equipment agnostic interface that

support equipment configuration. |

Each interface

specification will define the inputs, outputs and

behavior. Interfaces must conform to

the specification regardless of the technology used for implementation. |

|

|

Interfaces must

be flexible enough to evolve over time. Interfaces will implement a

versioning scheme to support evolution of an interface. |

We will only

define parts of the interface which are required not parts which “may” be

used in the future. An interface can

be update when in data points are required. |

|

|

A Platform

Independent Model (PIM) will define the data model. |

A PIM exhibits a specified

degree of platform independence so as to be suitable

for use with a number of different platforms of similar type |

|

|

Platform Specific

Models (PSM) shall implement the D-WIS data model. |

PSM combines the specifications in the PIM with the

details that specify how that system uses a particular type of platform. When defining a PSM

a target Platform Model has to be available. |

|

|

Interfaces must

support security |

Security should

be an intrinsic part of the interface. There should not be a requirement as

to which method of security to use. Governance and policies should define

security. |