Overall Description

The current

method of managing drilling signals across data suppliers and data consumers

during drilling operations requires perfectly aligned tag names as well as

communication protocols. Work Group 1 is

tasked with developing a plug and play methodology that does not require human

interface to match tag names. Others are

working on standardizing communication protocols.

Using a

semantic process, each machine/sensor or other element describes itself (what

it is and what it can

do) and provides this as real time information.

[Cayeux, 2019] This

allows adding and removing devices from a rig network without affecting

existing devices. The description of

every device shall be agreed beforehand using techniques based on the output of

this committee; namely by describing itself as interrelated facts of the form

Subject Verb Object. This creates a

semantic network containing the topological relationship between each device or

element that can be used to generate computer code to bridge between various

participants devices/elements. However,

new device names may be added at any time ...

Note that

the devices/elements could be hardware, like a controller or a sensor, or it

could be a computation, an estimate, or non-structured data such as a typed

report. An application that needs to

access information can query the semantic network for the signals that match

certain criteria. When the elements are

properly described, an application can understand the data, how and where it is

obtained and other metadata.

Furthermore, this metadata is stored along with the data for use in the

future should users need to reexamine the data years later.

This allows

drilling automation systems to:

· Discover and select required data, without prior knowledge of the rig signal set-up

o Get access to all the necessary information about the data

o Automatically configure the data transfer

· Get informed when rig signal set-up is modified

o Reconfigure itself

· Provide information about its own data

o Can be used by other systems

There are

some basic definitions that help explain the nature of this project.

The

SPE-subcommittee Drilling Data Quality

and Uncertainty has assembled a list of user cases / user pain points and

has begun to examine each in detail. The

work is currently incomplete and ongoing.

This document will be updated periodically as additional items are

examined.

![]()

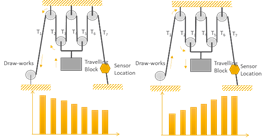

Example:

abnormal low hook-load detection and characterization

Scenario: A

simple quick drilling event detection application focused on abnormal low

hook-load would utilize semantic information.

Context:

The

application can detect an abnormal low hook-load with regards to a threshold

If

there is sufficient information, it can categorize the event between a ledge or

a pack-off

The

application should be able to distinguish an event from routine variations in

hook load due to sheave friction.

Capability:

It

can make use of:

Block

position, bit depth, bottom hole depth

Several

variants of hook-loads

Top-drive

speed and torque

Flowrate

and SPP

Several

sort of mud density in measurements/calculations

Downhole

ECD both through mud pulse and wired pipe

Data

producers:

Drilling

control system

Drilling

fluid provider

Mud

logging provider

Downhole

measurements